SoftGrip Project

About the Project

The white button mushroom (Agaricus bisporus) is the most widely cultivated mushroom in the world (15-36% of total market share). More than 60% of this production is destined for the fresh market, while the rest are processed and canned. Whereas for the canned industry mushrooms can be harvested and handled by an automated system, such automation does not yet exist for picking and handling mushrooms for the fresh market, due to the high quality standards required by this product. The actual picking of the mushroom is still done manually, due to the dexterity, precision and sensitivity of the human hand that can pick the mushroom and not damage it. However, the actual work of picking mushrooms is one of the most physically demanding in the agro sector, given the setup of the shelves and the humidity of the growing rooms, causing high incidences of sick leave in detriment to both the workers and their employers.

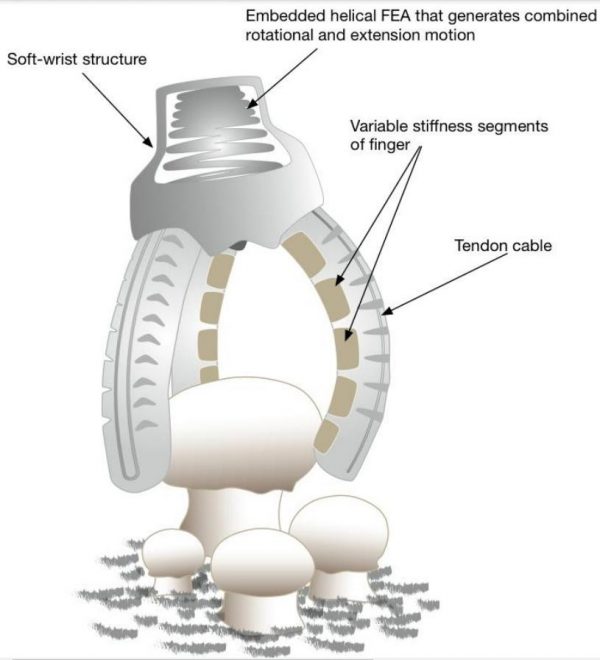

SoftGrip will introduce a self-actuating soft robotic gripper for the autonomous picking of delicate white button mushrooms. The project aims for low-cost, intelligent soft robotic grippers with embedded actuation, tactile sensing, recyclable materials, and advanced fabrication techniques. It will develop a set of fast-computed modelling algorithms to enhance real-time model-based control schemes and advanced learning capabilities of the soft gripper. SoftGrip aims to develop a learning-by-demonstration framework that will allow the robot to capture the mushroom picking skill (as demonstrated by the human worker) in a way that is extensible to other similar tasks.